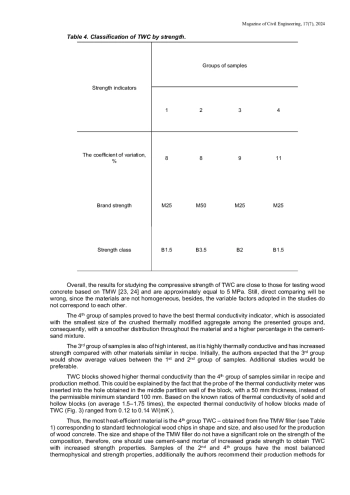

The paper studies the ways that technological characteristics of thermal wood concrete (TWC) production have on its strength and thermal conductivity properties. TWC is a new, effective wood-cement composition of authors’ development. To produce it the authors used crushed thermally modified wood (TMW) with a certain shape and size as a filler. The research is rationalized by the fact that currently we are facing a lack of both fundamental and applied experimentally confirmed data on TWC. The paper discusses the studies of the compressive strength and thermal conductivity of four groups of TWC samples that were obtained with three types of filler, differing in size and shape, molding method and strength class of cement-sand mortar. The authors determined general impact patterns of the above-mentioned factors on strength and thermal conductivity properties, as well as specific indicators. Moreover, the paper describes the strength classes and grades of TWC that ranged from B1.5 to B3.5 and from M25 to M50, respectively. Thermal conductivity for standard samples ranged from 0.21 to 0.4 W/(mK). It has been concluded that TWC with a finer TMW filler has the most balanced combination of strength, thermal conductivity and deformation properties. Following the results, the authors proposed practical recommendations for TWC production, and further courses for its improvement and research.

Идентификаторы и классификаторы

While developing new materials, an important task is seen in acquiring fundamental knowledge on their operational, technological and other properties. Thermowood-cement composition or thermal wood concrete (TWC) is a new, previously unstudied building material of original development. The paper studies its strength, thermal conductivity properties, as well as technological factors that influence them. Standard TWC samples made in the laboratory are the objects under study.

Список литературы

1. Gornostaeva, E.Yu., Gornostaeva, E.Yu., Lasman, I.A., Fedorenko, E.A., Kamoza, E.V. Wood-cement compositions with structures modified at macro-, micro-, and nano-levels. Stroitel’nye Materialy [Construction Materials]. 2015. 11. Pp. 13−16.

2. Nanazashvili, I.Kh. The “quick-to-erect” low-rise monolith buildings from the arbolite. Part 1. Construction Materials, Equipment, Technologies of the XXI Century. 2009. 11. Pp. 14–15.

3. Nanazashvili, I.Kh. Proizvodstvo arbolita iz drevesnyh othodov [Production of wood concrete from wood waste]. Moscow: CBNTI Minpromstroya SSSR, 1974. 47 p.

4. Krutov, P.I. Sklizkov, N.I., Nanazashvili, I.Kh., Sirotkina, R.B., et al. Ispol’zovanie othodov drevesiny dlya polucheniya effektivnyh stroitel’nyh materialov: Obzor [The use of wood waste to produce efficient building materials: Review]. Moscow: ONTI TsNIIEPselstroy, 1978. 24 p.

5. Sanaev, V.G., Zaprudnov, V.I., Gorbacheva, G., Oblivin, A.N. Factors affecting the quality of wood-cement composites. Bulletin of the Transilvania University of Braşov. Series II: Forestry. Wood Industry. Agricultural Food Engineering. 2016. 9(58). Pp. 63–70.

6. Safin, R.G., Stepanov, V.V., Khairullina, E.R., Gainullina, A.A., Stepanova, T.O. Modern building composite materials based on wood waste. Bulletin of the Kazan Technological University. 2014. 17(20). Pp. 123–128.

7. Fu, Q.N., Yan, L., Thielker, N., Kasal, B. Effects of Concrete Type, Concrete Surface Conditions and Wood Species on Interfacial Properties of Adhesively-bonded Timber – Concrete Composite Joints. International Journal of Adhesion and Adhesives. 2021. 107. Article no. 102859. DOI: 10.1016/j.ijadhadh.2021.102859

8. Nemati, G.A., Fu, Q.N., Yan, L., Kasal, B. The effect of adhesive amount and type on failure mode and shear strength of glued timber-concrete joints. Construction and Building Materials. 2022. 345. Article no. 128375. DOI: 10.1016/j.conbuildmat.2022.128375

9. Khajrullina, E.R., Safin, R.G., Tuntsev, D.V., Khajrullina, M.R. The effectiveness of the use of pretreatment of wood filler in the production of wood-cement composition. Systems. Methods. Technologies. 2021. 3(51). Pp. 85–91. DOI: 10.18324/2077-5415-2021-3-85-91

10. Long, Xi., Liu, Z., Li, Xi., Zhou, H., Han, Ch. Surface modification of wood and its effect on the interfacial bonding properties of cement-based wood composites. European Journal of Wood and Wood Products. 2023. 81. Pp. 897–909. DOI: 10.1007/s00107-023-01926-7

11. Ramdane, R., Leila, Kh., Assia, A., Belachia, M. Influence of Biomass Ash on the Performance and Durability of Mortar. Civil and Environmental Engineering Reports. 2022. 32(2). Pp. 53–71. DOI: 10.2478/ceer-2022-0019

12. Verma, Sh., Singh, A., Gupta, R., Sundriyal, S. The Effect of Wood Ash on the Workability, Water Absorption, Compressive Strength in Cement Mortar. International Journal for Modern Trends in Science and Technology. 2023. 9(4). Pp. 368–373. DOI: 10.46501/IJMTST0904054

13. Kostic, S., Merk, V., Berg, J., Hass, P., Burgert, I., Cabane, E. Timber-mortar composites: The effect of sol-gel surface modification on the wood-adhesive interface. Composite Structures. 2018. 201. Pp. 828-833. DOI: 10.1016/j.compstruct.2018.06.108

14. Liu, Z., Han, Ch., Li, Q., Li, Xi., Zhou, H., Song, Xi., Zu, F. Study on wood chips modification and its application in wood-cement composites. Case Studies in Construction Materials. 2022. 17. Article no. e01350. DOI: 10.1016/j.cscm.2022.e01350

15. Liu, Z., Han, Ch., Li, Xi., Zhou, H., Song, Xi., Zu, F. Study on Wood Chips Modification and its Effect on the Mechanical Properties of Wood-Cement Composite Material. SSRN Electronic Journal. 2022. DOI: 10.2139/ssrn.4020085

16. Hill, C., Stevens, C.V. Wood Modification: Chemical, Thermal and Other Processes. John Wiley and Sons, Ltd, 2006. 239 p.

17. Altgen, M., Adamopoulos, S., Militz, H. Wood defects during industrial-scale production of thermally modified Norway spruce and Scots pine. Wood Material Science & Engineering. 2017. 12. Pp. 14–23. DOI: 10.1080/17480272.2014.988750

18. Boonstra, M.J., Van Acker, J., Kegel, E.M. Optimisation of a two-stage heat treatment process: durability aspects. Wood Science and Technology. 2007. 41. Pp. 31–57. DOI: 10.1007/s00226-006-0087-4

19. Cai, Ch., Heräjärvi, H., Haapala, A. Effects of environmental conditions on physical and mechanical properties of thermally modified wood. Canadian Journal of Forest Research. 2019. 49(11). Pp. 1434–1440. DOI: 10.1139/cjfr-2019-0180

20. Hill, C., Altgen, M., Rautkariauri, L. Thermal modification of wood – a review: chemical changes and hygroscopicity. Journal of Materials Science. 2021. 56(11). Pp. 6581–6614. DOI: 10.1007/s10853-020-05722

21. Militz, H. Thermal treatment of wood: European processes and their background. The 33rd annual meeting of The International Research Group on Wood Preservation, 12–17 May. Cardiff, 2002. 4. Pp. 1–17.

22. Hakkou, M., Petrissans, M., Gerardin, P., Zoulalian, A. Investigations of the reasons for fungal durability of heat-treated beech wood. Polymer Degradation and Stability. 2006. 91(2). Pp. 393–397. DOI: 10.1016/j.polymdegradstab.2005.04.042

23. Hasanshin, R.R. Thermal modification of wood filler in the production of composite materials. Doctoral dissertation. Kazan National Research Technological University, 2019.

24. Guo, A., Bu, A., Osama, A.O., Satyavolu, J., Sun, Zh. Impact of thermally modified wood on mechanical properties of mortar. Construction and Building Materials. 2019. 208. Pp. 413–420. DOI: 10.1016/j.conbuildmat.2019.03.016

25. Chernov, V.Yu., Gaisin, I.G., Palkin, A.A., Maltseva, E.M. The Concrete Based on TMW Filler: Features of the Material and Prospects of Use. Actual Problems and Prospects for the Development of the Timber Industry: Materials of the IV International Scientific-Practical Conference. Kostroma: Kostroma State University, 2021. Pp. 103–106.

26. Chernov, V.Yu., Sharapov, E.S., Mal’tseva, E.M., Pegushina, E.N. Investigation of the effect of thermal modification of wood on the adhesive and strength properties of a wood-cement composition. Bulletin of MGSU. 2023. 18(9). Pp. 1394–1407. DOI: 10.22227/1997-0935.2023.9.1394-1407

Выпуск

Другие статьи выпуска

The work is devoted to the study and analysis of hydrodynamic and climatic loads on hydraulic structures of the Neva Bay – the eastern part of the Gulf of Finland, which is exposed to significant anthropogenic and natural impacts. The geographical position of the Neva Bay, as well as the complex of flood protection structures of St. Petersburg, affect the predicted load levels. In these conditions, special attention is paid to the design and operation of pontoons and other hydraulic structures resistant to waves, ice cover and wind loads. The study calculated the wave-protective characteristics and stability of pontoons used in the Neva Bay as moorings for small vessels. The main parameters of wave loads were estimated using wave models, which made it possible to take into account irregular water oscillations and their effect on the dynamic behavior of structures. A test was carried out for the stability of pontoons with various configurations of anchor systems that ensure their fixation at a given point in the water area. The simulation showed that under conditions of irregular waves and changing water levels, floating structures experience significant loads that are distributed to the anchor system and require accurate calculations to ensure reliability. Additionally, ice and wind load on hydraulic structures, loads associated with thermal expansion of ice, changes in water levels, and wind effects were studied, taking into account the characteristics of ships of different lengths and above-water heights. The simulation results make it possible to identify key operating conditions for protective and berthing structures in the Neva Bay and provide information for inclusion in the information model of the water area, which will allow predicting the behavior of structures under changing natural and climatic conditions.

About 2,200 km3 of wastewater is discharged into the environment annually: municipal (including households), industrial and agricultural (including drainage water) – at the same time, as indicated in the UN World Report on the State of Water Resources for 2023. Over the past 40 years, global water use has been increasing by about 1 % per year and is expected to grow at this rate until 2050 as a result of the combined impact of factors, such as population growth, socio-economic development and climate change consumption patterns. With increasing consumption of water resources, the volume of their pollution increases, which creates serious environmental, economic and social problems. In this regard, the preservation of water and food security through sustainable management of water resources, universal quality provision of water supply and sanitation services are global problems all over the world and require an integrated approach involving government agencies, private business, academia and public organizations. The water supply and sewerage industry has an extremely important social character, as it directly affects the health of the population and the environment. This requires the use of new effective environmentally friendly technologies for cleaning blockages and improving the mechanical characteristics of sewer pipelines, which will significantly increase their service life and reduce repair costs. The conducted studies have proved the effectiveness of using small-sized ultrasonic devices with an ultrasonic generator with a power of 0.1–10 kW, a frequency of 20–40 kHz, and a magnetostrictive transducer.

Chemical stabilization is a typical method for enhancing salinity in soils. In this regard, an effort has been made to evaluate the effect of chemical substances and stabilizers of Portland cement on the geotechnical characteristics of salt soils. Due to their geologic makeup, textural characteristics, and climatic factors, the majority of the soils in the southern part of Iraq are notable for having a wide variety of formations. Because the soil particles in the saline regions of Thi-Qar governorate are encircled by molecules of chlorides, sulfates, or other salt species that function as link agents to fill in the gaps in the dry state, these soils may generally be categorized as saline soils. The sort of salt in such soil determines how it should be disposed of. The objective of this study is to investigate the effect of adding different types of salt compounds including NaCl, MgCl2, Na2SiO3, and CaCl2 with various percentages 2, 4, 8, and 10 % and Portland cement for improving the consistency limits and shear strength of saline soft soils. It was found that adding cement materials and a group of chlorides NaCl, MgCl2, Na2SiO3, and CaCl2 increased the unconfined compressive strength of the soil from 290 to 814, 506, 404, 574, and 422 kPa, respectively, and decrease the consistency limits.

The requirements for reliability and durability are increasing every year for the critical elements of bridge structures, as there is a steady increase in the number of vehicles and volumes of cargo movement. Such structural elements include bearing parts of spans of bridges, which perceive loads from the mass of spans, transport cargo and compensate for deformations from thermal expansion and contraction. Antifriction polymeric materials are used in all newly developed designs of bearing parts. The reliability and durability of bridges as a whole depend on the physical, mechanical and operational properties of such materials. The change in the length of spans due to temperature fluctuations is carried out due to sliding along the polymer layers. The article presents a critical analysis of the polymer and metal-polymer materials used as sliding supports. A review and analysis of standardized anti-friction materials for possible use as sliding layers in the bearing parts of bridges have been carried out. The most promising fluoroplastic composite materials capable of operating without lubricant are presented. An analysis of metal-fluoroplastic sheet materials was made, new metal composites were proposed, in which various mesh materials with a high polymer content in the working layer are used as an anti-friction layer. Such materials can be used as guides for the moving bearing parts of the bridge without the use of lubricants. It is shown that the use of the described modern wear-resistant anti-friction materials will significantly increase the bearing capacity and service life of sliding bearings.

Utilization of ground granulated blast furnace slag (GGBFS) and fly ash (FA) to resolve the problem of increasing discharged and total accumulated industrial waste has attracted public concern. This article presents the research results on the effect of the replacement of up to 60 wt.% cement with GGBFS and FA, separately and in combination. It shows that mineral admixtures improve the workability of concrete mixture and reduce the required water-reducing admixture to reach a defined slump, prolonging the setting time of fresh concrete. The compressive strength of concrete with GGBFS at an early age decreases while increasing at 60 days and 90 days with the GGBFS content from 20 wt.% to 40 wt.%. The compressive strength of concrete with FA well develops at a later age, but it decreases at all ages as the FA replacement ratio increases. Cement replacement with a combined mineral admixture of 20 wt.% GGBFS and 20 wt.% FA does not significantly change the compressive strength at 28 days and later. Based on test result

Foam solution discharge is always accompanied by changes in the operating pressure due to different pressure losses along the pipeline in automatic foam extinguishing systems. Changes in the operating pressure affect the process of a liquid jet fragmentation into droplets and the formation of foam films. Therefore, to increase the accuracy of calculations when designing automatic foam extinguishing systems, it is worthwhile to evaluate the main characteristics of the foam in terms of fire extinguishing efficiency, in particular, its expansion. For this purpose, the generalization of the experimental data using the theory of similarity and taking into consideration the hydrodynamic features of the deflector type sprinkler operation and the properties of foam solution was carried out to develop a novel simplified mathematical model. This model allows to predict the foam expansion depending on the geometric parameters of the sprinkler elements and the empirical coefficient, which takes into account the peculiarities of the chemical composition of the foam concentrate. This new model predictions of foam expansion show good agreement with the experimentally measured foam expansion. The average error in foam expansion was less than 9 %.

The paper is devoted to the issues of predicting the temperature distribution in asphalt concrete layers in different periods of the year. Mechanical parameters of asphalt concrete strongly depend on its temperature. The reliability of the temperature dependence used for temperature prediction directly determines the reliability of calculation methods for motorway pavements design. At the same time, it should be noted that many existing models describe the temperature distribution along the depth of the asphalt concrete layer package with a rather large degree of error and are not calibrated for the conditions of the Russian Federation. Methods. The approach proposed by the authors is based on the study of the actual temperature distribution in asphalt concrete pavements by analyzing data from a set of measuring sensors installed at different depths of the asphalt concrete pavement package. The actual temperature distribution was monitored during the annual cycle from March 2023 to April 2024. Results. To approximate the results obtained, a dependence describing the sinusoidal nature of temperature variation on the surface and in the asphalt concrete layers was modified. Modification of the dependence was carried out by introducing an additional empirical parameter characterizing the dependence of the change in the absolute temperature value on the depth. The accuracy of the modified dependence is confirmed by the root mean square error (RMSE) value of up to 10 %. Conclusions. The model modified in the paper can be used at the stage of design and operation of motorways when calculating the temperature conditions of asphalt concrete layers.

Статистика статьи

Статистика просмотров за 2025 - 2026 год.

Издательство

- Издательство

- Политех

- Регион

- Россия, Санкт-Петербург

- Почтовый адрес

- 195251, г.Санкт-Петербург, ул. Политехническая, дом 29

- Юр. адрес

- 195251, г Санкт-Петербург, Калининский р-н, ул Политехническая, д 29 литера б

- ФИО

- Рудской Андрей Иванович (РЕКТОР)

- E-mail адрес

- office@spbstu.ru

- Контактный телефон

- +7 (812) 2972077

- Сайт

- https://spbstu.ru