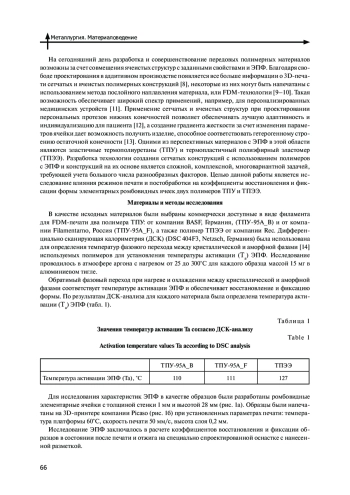

В работе исследовано влияние режимов печати FDM-технологии и термообработки отжигом на коэффициенты восстановления к первоначальной форме и фиксации временной формы на образцах из эластичных полимеров с эффектом памяти формы. Эксперименты показали, что для всех исследуемых полимеров наибольшее значение коэффициента восстановления формы достигается с помощью выбора режима печати с верхней границей в интервале температуры экструзии, рекомендованном производителем, и последующего проведения отжига для снятия остаточных напряжений. Результаты проведенных исследований показали наилучшие значения коэффициента восстановления и фиксации формы, равные 98,6% и 94,5% соответственно.

Идентификаторы и классификаторы

Введение. Аддитивное производство изделий из полимерных и металлических материалов в настоящее время уже является реальностью для многих отраслей передового производства. Однако существует сегмент, который считается будущим аддитивного производства, – это передовые или современные материалы. К передовым материалам на полимерной основе относятся полимеры семейства PAEK, а также 4D-материалы c ячеистыми структурами и эффектом памяти формы (ЭПФ) [1].

Список литературы

1. Advanced Materials. How cutting edge materials are shaping the future of additive manufacturing. 3D Printing Business Media Ltd., 2020. Режим доступа: https://www.voxelmatters.com/wp-content/uploads/2020/04/3dpbm-publishes-Advanced-Materials-am-focus-2020-ebook.pdf.pdf (дата обращения: 25.12.2023).

2. Ratna D., Karger-Kocsis J. Recent advances in shape memory polymers and composites: a review // Journal of Materials Science. 2008. Vol. 43. P. 254-269. DOI: 10.1007/s10853-007-2176-7 EDN: YAATLF

3. Grima J., Caruana-Gauci R. Materials that push back // Nature materials. 2012. Vol. 11. Iss. 7. P. 565-566. DOI: 10.1038/nmat3364

4. Bai L., Gong C., Chen X., Sun Y., Xin L., Pu H., Luo J. Mechanical properties and energy absorption capabilities of functionally graded lattice structures: Experiments and simulations // International Journal of Mechanical Sciences. 2020. Vol. 182. Art. no. 105735. DOI: 10.1016/j.ijmecsci.2020.105735 EDN: GGUUYZ

5. Rafsanjani A., Akbarzadeh A., Pasini D. Snapping mechanical metamaterials under tension // Advanced Materials. 2015. Vol. 27. Iss. 39. P. 5931-5935. DOI: 10.1002/adma.201502809

6. Janbaz S., McGuinness M., Zadpoor A.A. Multimaterial control of instability in soft mechanical metamaterials // Physical Review Applied. 2018. Vol. 9. Iss. 6. Art. no. 064013. DOI: 10.1103/PhysRevApplied.9.064013

7. Wang Q., Li Z., Zhang Y., Cui S., Yang Z., Lu Z. Ultra-low density architectured metamaterial with superior mechanical properties and energy absorption capability // Composites Part B: Engineering. 2020. Vol. 202. Art. no. 108379. DOI: 10.1016/j.compositesb.2020.108379 EDN: MLXTNA

8. Sadeghi F., Baniassadi M., Shahidi A., Baghani M. TPMS metamaterial structures based on shape memory polymers: Mechanical, thermal and thermomechanical assessment // Journal of Materials Research and Technology. 2023. Vol. 23. P. 3726-3743. DOI: 10.1016/j.jmrt.2023.02.014 EDN: DSHYJW

9. Beloshenko V., Beygelzimer Y., Chishko V., Savchenko B., Sova N., Verbylo D., Vozniak I. Mechanical properties of flexible TPU-based 3D printed lattice structures: role of lattice cut direction and architecture // Polymers. 2021. Vol. 13. Iss. 17. Art. no. 2986. DOI: 10.3390/polym13172986 EDN: VPYMXK

10. Mishra A.K., Chavan H., Kumar A. Effect of material variation on the uniaxial compression behavior of FDM manufactured polymeric TPMS lattice materials // Materials Today: Proceedings. 2021. Vol. 46. P. 7752-7759. DOI: 10.1016/j.matpr.2021.02.276 EDN: DZPRPK

11. Pal A.K., Mohanty A.K., Misra M. Additive manufacturing technology of polymeric materials for customized products: recent developments and future prospective // RSC Advances. 2021. Vol. 11. Iss. 58. P. 36398-36438. DOI: 10.1039/D1RA04060J EDN: IYFMAX

12. Абдрахманова А.Э., Сотов А.В., Зайцев А.И., Попович А.А. Обзор применения аддитивных технологий в медицине: перспективы функционально-градиентных полимеров в протезировании нижних конечностей // Глобальная энергия. 2023. Т. 29, № 4. С. 83-96. DOI: 10.18721/JEST.29405 EDN: OJLYYT

13. Devin K.M., Tang J., Hamilton A.R., Moser D., Jiang L. Assessment of 3D printed mechanical metamaterials for prosthetic liners // Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine. 2024. Vol. 238. Iss. 3. P. 348-357. DOI: 10.1177/09544119231225529 EDN: QVJMKC

14. Dayyoub T., Maksimkin A.V., Filippova O.V., Tcherdyntsev V.V., Telyshev D.V. Shape memory polymers as smart materials: a review // Polymers. 2022. Vol. 14. Iss. 17. Art. no. 3511. DOI: 10.3390/polym14173511 EDN: KFVUUO

Выпуск

Другие статьи выпуска

В данной работе исследовано влияние различных параметров процесса селективного лазерного плавления (СЛП) на формирование дефектов и микроструктуры в жаропрочных никелевых сплавах. Экспериментальные образцы были изготовлены с использованием установки “ВПЛС Меркурий”, оснащенной системой индуктивного высокотемпературного подогрева. Путем варьирования энергетических параметров СЛП были получены данные о зависимости линейной плотности энергии от количества и типов возникающих дефектов, таких как макротрещины и микродефекты. Результаты исследования показали, что увеличение линейной плотности энергии способствует значительному снижению дефектов в структуре образцов. На основании проведенного анализа также выявлены особенности формирования микроструктуры и причины возникновения дефектов при различных режимах СЛП. Полученные результаты могут быть использованы для оптимизации параметров процесса и улучшения качества изделий из жаропрочных никелевых сплавов, изготовленных методом аддитивного производства.

Остаточный аустенит является очень важной структурной составляющей, особенно в высоколегированных и высокоуглеродистых сталях. При определенном легировании и термической обработке его количество может составлять до 95–98%. Поэтому существенное значение имеет определение температуры начала мартенситного превращения (мартенситной точки) в зависимости от химического состава. В настоящее время однозначного выражения этой зависимости не существует. Исследователи используют многочисленные расчетные модели и экспериментальные данные. В настоящей работе рассмотрена зависимость мартенситной точки от содержания углеродов в сталях, легированных некарбидообразующим элементом – никелем. В работе использован структурный метод определения мартенситной точки с применением высокотемпературной металлографической установки. Показано, что наибольшее влияние на мартенситную точку никель оказывает в низкоуглеродистых сталях. С повышением содержания углерода влияние никеля ослабевает, а для стали 143Н4 мартенситная точка находится даже выше, чем в углеродистой стали с аналогичным содержанием углерода. Установлено, что при высоком содержании углерода даже при быстром охлаждении происходит графитизация, что и следует считать причиной повышения мартенситной точки. Материалы статьи были представлены на Международной научно-практической конференции «Перспективные машиностроительные технологии (Advanced Engineering Technologies) AET 2024», проходившей в Санкт-Петербурге 13–16 мая 2024 года.

Данная работа посвящена исследованию распределения температурных полей при точечной сварке трением с перемешиванием (ТСТП) алюминиевых листов толщиной 2 мм из АМг5 и В95АТ при помощи компьютерного моделирования. Модель создавалась в программном комплексе для моделирования процессов обработки металлов давлением DEFORM-2D/3D. В результате работы была создана модель процесса ТСТП для алюминиевых сплавов АМг5 и В95АТ, которая была верифицирована по экспериментальным данным измерения температур с помощью термопар. С помощью верифицированной модели было исследовано влияние параметров процесса на температурные поля алюминиевых сплавов. Результаты исследования показали, что основное влияние на повышение температуры при ТСТП оказывает скорость вращения инструмента, а также теплопроводность самого материала. Усложнение геометрии заплечика, в частности нанесение резьбы, дополнительно увеличивает тепловыделение и скачкообразное поведение температуры.

В работе представлены результаты исследования влияния температуры подогрева платформы при селективном лазерном плавлении (СЛП) и термической обработке на микроструктуру, фазовый состав и механические свойства хромистой стали. Была выявлена зависимость пористости компактного материала от плотности энергии селективного лазерного плавления. Микроструктура образцов характеризуется узкими, вытянутыми вдоль направления построения зернами. При печати с подогревом платформы средняя длина зерен увеличивается с 156 до 563 мкм, средняя ширина при этом не изменяется и составляет около 30 мкм. После термической обработки на границах зерен выделились включения, предположительно карбиды типов MC и M23C6. Дифрактограммы образцов содержат пики, соответствующие объемно-центрированной кубической решетке. Подогрев платформы в процессе СЛП позволил повысить пластичность материала на 6% (с 12 до 18%) при сохранении прочностных свойств. Результаты показали, что применение подогрева платформы и термической обработки позволяют изменять микроструктуру и механические свойства. Материалы статьи были представлены на Международной научно-практической конференции «Перспективные машиностроительные технологии (Advanced Engineering Technologies) AET 2024», проходившей в Санкт-Петербурге 13–17 мая 2024 года.

Исследованы перспективы достижения углеродной нейтральности крупнейшими развивающимися странами (Китай, Индия, Индонезия, Бразилия, Иран, Саудовская Аравия). Выполнен анализ структуры энергетики и землепользования в этих странах. Разработаны сценарные оценки динамики углеродных показателей экономик исследуемых стран. Показано, что существующие темпы декарбонизации и развития индустрии улавливания и хранения углерода (CCS) в исследуемых странах не позволяют выполнить их обязательства по достижению климатической нейтральности в 2050–2070 гг. – эта цель не может быть достигнута ранее конца столетия. Центральной проблемой в достижении климатической нейтральности становится быстрое и масштабное внедрение технологий CCS во всех ее возможных проявлениях. Однако из исследованных стран только Китай и Бразилия располагают собственными возможностями для захоронения углерода на период более ста лет. Несмотря на то, что изменения климата занимают едва ли не лидирующее место в мировой повестке, действительные результаты усилий в этой области далеки от декларируемых и сдержать потепление в пределах 1,5°C сейчас уже невозможно. Ключевой задачей становится максимальное сокращение времени пребывания глобальной климатической системы в опасной запредельной зоне (выше 1,5°C), что потребует создания мировой экономики с отрицательной эмиссией парниковых газов.

К середине века выработка электроэнергии вырастет более чем в два раза, что приведет к увеличению количества парниковых газов, которые усиливают глобальное потепление. Одним из наиболее перспективных циклов по выработке электрической энергии является цикл Брайтона со сверхкритическим диоксидом. Рабочее тело обладает высокой мощностью освещения, стабильными термическими и химическими методами. Для более глубокого исследования газодинамических и прочностных характеристик проточной турбины, работающей на сверхчастичном критическом диоксиде, необходимо создание полномасштабного натурного экспериментального стенда. Однако свойства рабочего тела не до конца изучены, создание природного стенда требует высоких затрат и повышенных мер безопасности, так как его работа требует соблюдения значений температуры и давления. В работе проводилось моделирование сверхкритического диоксида, подаваемого на воздух с использованием аналогичной методики. Для проверки перечисленных экспериментов, проведенных в программном комплексе Ansys Workbench, был выбран экспериментальный стенд, расположенный на базе Санкт-Петербургского политехнического университета Петра Великого. Проведена комплексная оценка технического состояния стенда, произведена замена и модернизация некоторых узлов. В рамках подготовки стенда выполнены погодные условия и тщательные расчеты подшипника. Разработаны и изготовлены новые форсунки подачи масла в подшипники. Проведены испытания масляной системы, которые показывают, что объемный расход соответствует стандартным значениям технического паспорта подшипника. Выполнен замер объема расхода водяной системы. Была разработана современная измерительная система, обеспечивающая точность экспериментов и позволяющая в настоящее время основные характеристики турбин для текущих экспериментальных исследований.

Статистика статьи

Статистика просмотров за 2025 - 2026 год.

Издательство

- Издательство

- Политех

- Регион

- Россия, Санкт-Петербург

- Почтовый адрес

- 195251, г.Санкт-Петербург, ул. Политехническая, дом 29

- Юр. адрес

- 195251, г Санкт-Петербург, Калининский р-н, ул Политехническая, д 29 литера б

- ФИО

- Рудской Андрей Иванович (РЕКТОР)

- E-mail адрес

- office@spbstu.ru

- Контактный телефон

- +7 (812) 2972077

- Сайт

- https://spbstu.ru